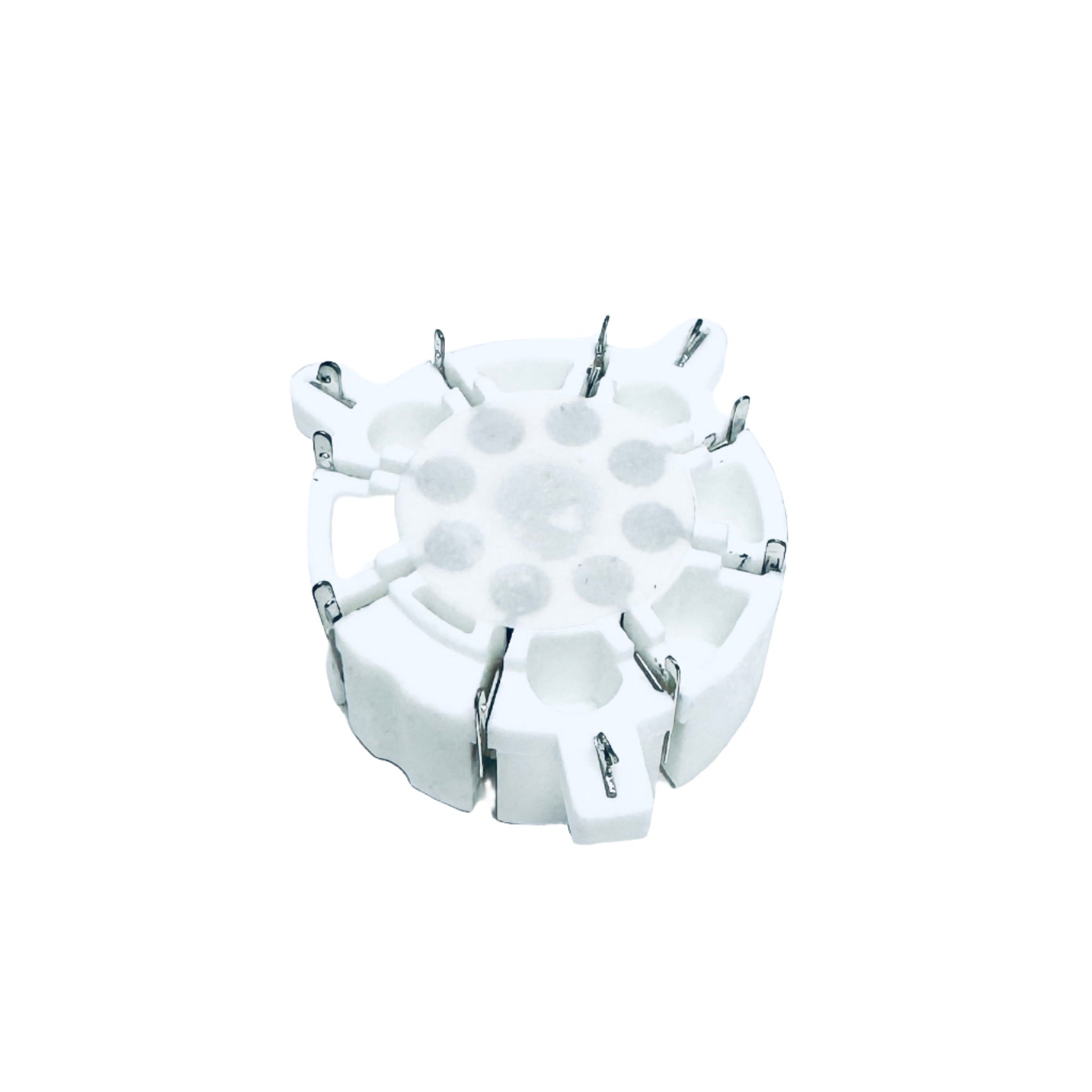

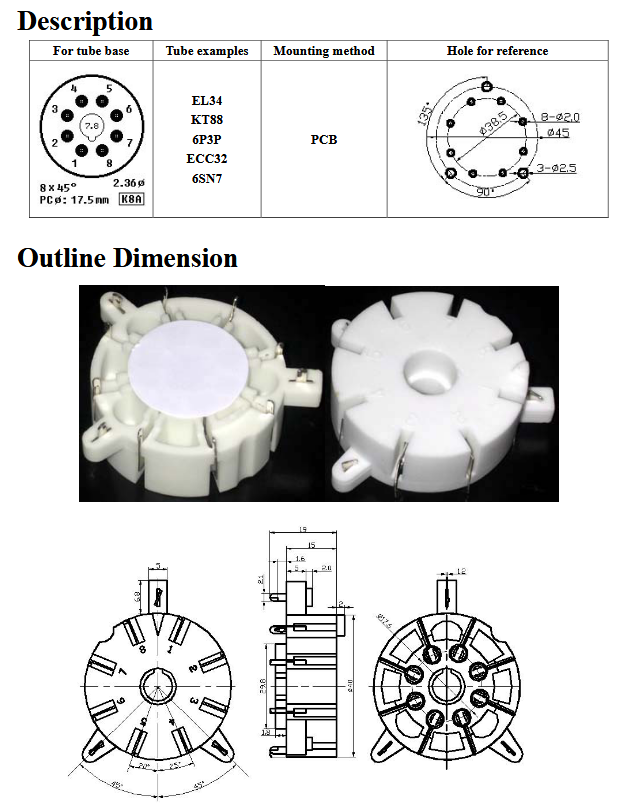

Ceramic 8 Pin PCB Mount Reverse Socket - TUS8PC8C

Introducing the Ceramic 8 Pin PCB Mount Reverse Socket - TUS8PC8C, a high-quality and durable option for your PCB mounting needs. With its ceramic material and reverse socket design, it provides reliable and secure connections. Make sure your PCB is in good hands with this expertly crafted socket.