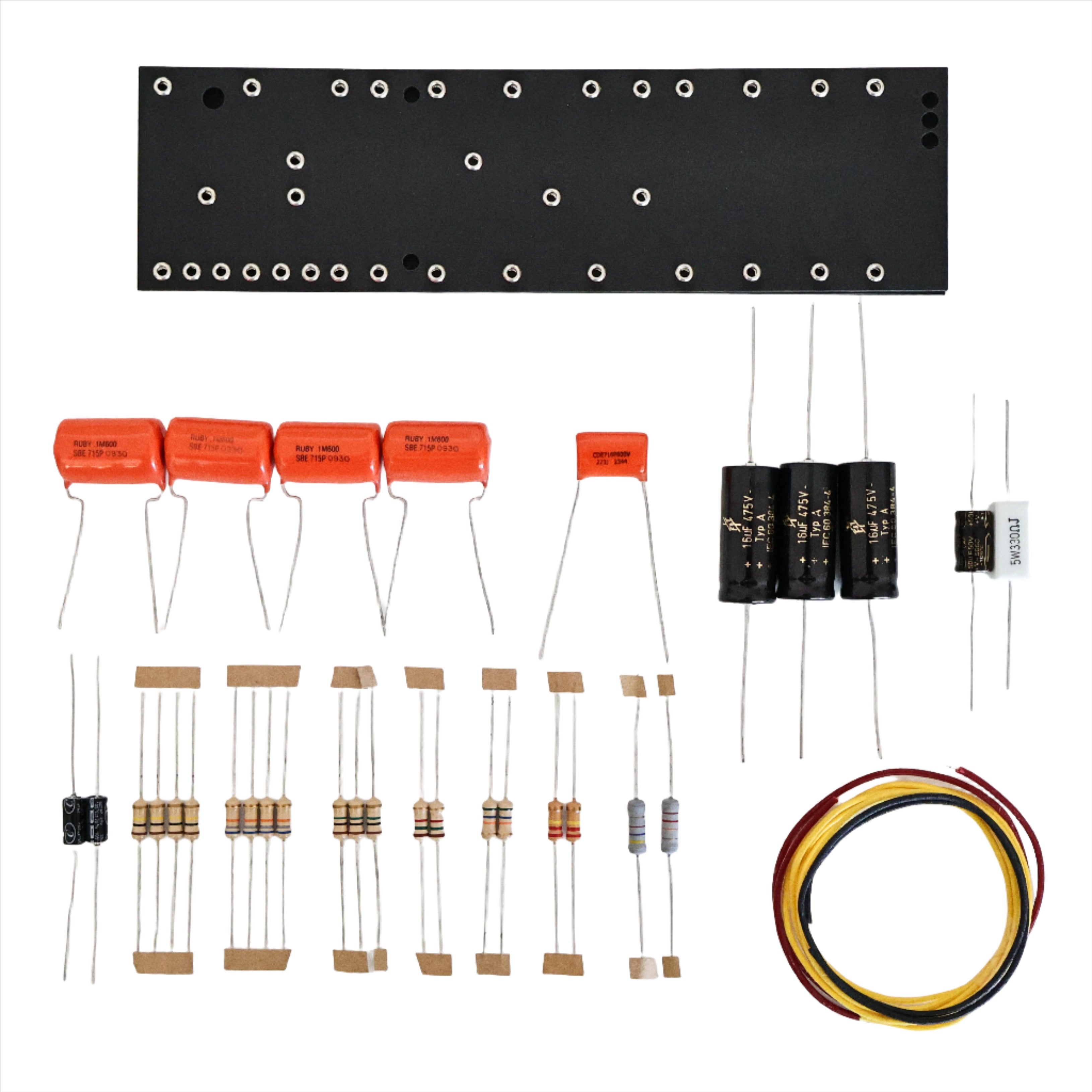

The Bias Circuit Capacitor 50mfd @ 100V is an electrolytic capacitor commonly used in tube amplifier bias circuits. With a capacitance of 50 microfarads and a voltage rating of 100 volts, it helps filter and stabilize the negative bias voltage supplied to power tubes. This ensures consistent performance and reduces hum or noise. Its high voltage rating makes it suitable for vintage and modern amp designs alike.